Our Heritage

Economic Activities

Asan leading the Seosan Reclamation project, impressing the world with his innovative approach of using oil tankers to block currents and fill the bay with soil (1984).

Construction

Following colonial rule and a war that devastated the country, infrastructure was urgently needed to get the country back on its feet.

Faced with doubts about the lack of capital and technology, and voices fearful of failure, Asan stepped forward believing construction could transform despair into hope—and he succeeded.

Asan extended his efforts beyond the Korean Peninsula, dreaming and fostering prosperity out of ruins worldwide.

As a leading construction company, Hyundai Engineering & Construction has carried forward Asan's legacy through top-tier technologies and creative solutions in civil engineering, architecture, infrastructure, electricity, and nuclear energy sectors.

“ Leave everything to me.

If you are scared, go home and wait. ”

Overseeing the launch of a 260,000-ton VLCC in 1974

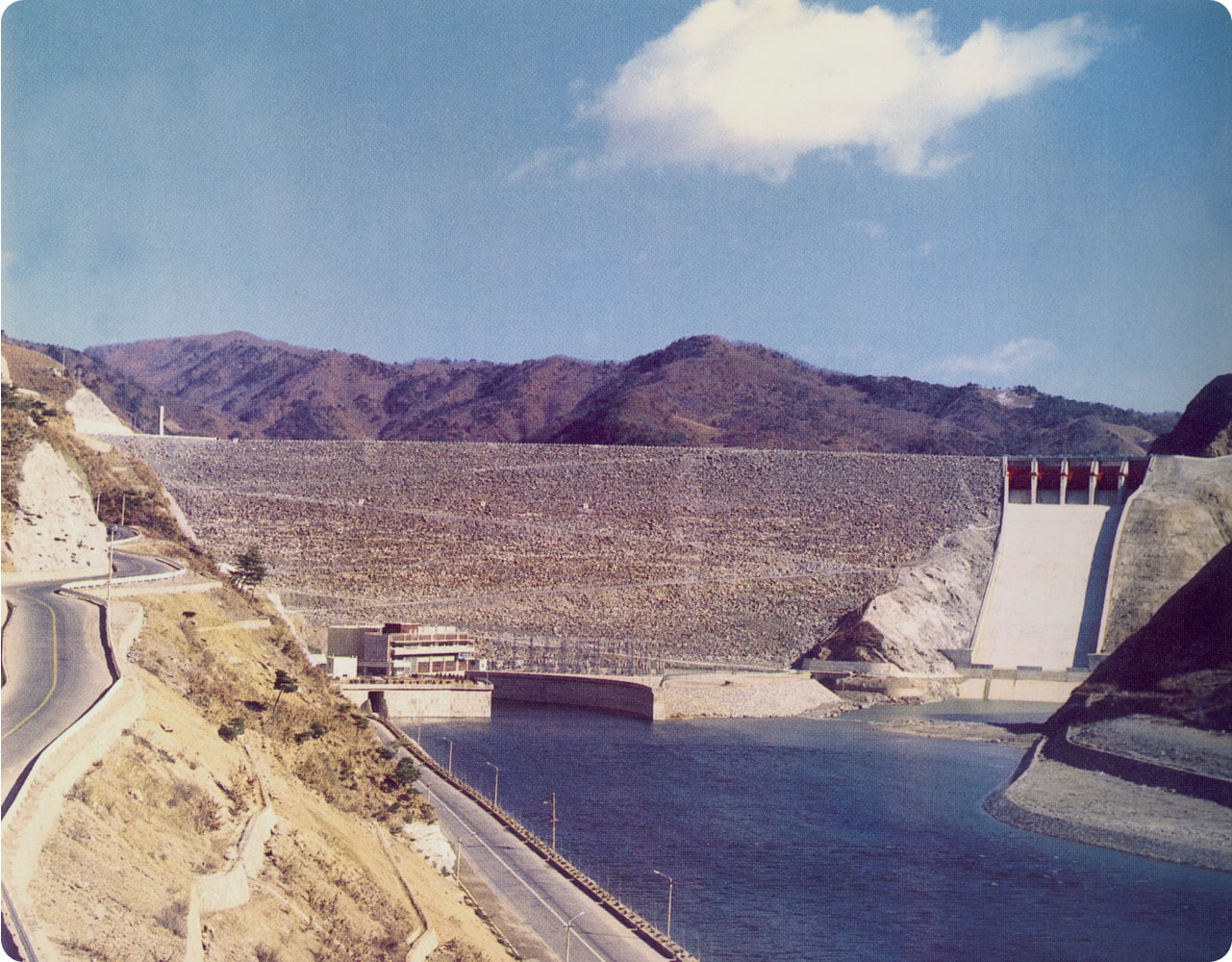

Constructed by Asan, the multi-purpose Soyang River Dam was a rockfill dam instead of a concrete dam, significantly reducing construction costs. (1973)

Soyang River Dam

The Soyand River Dam project was a large-scale project for flood control. However, there were issues with domestic cement supply along with a lack of construction experience. meaning foreign engineers had to be hired to design and build the dam. Nevertheless, Asan was determined to build the dam with our own hands.

Unfazed by skepticism, Asan used the soil and gravel around the Soyang River to construct an rockfill dam.

Establishment of Hyundai Cement

As construction projects increased, domestic cement production always fell short, leading to higher reliance on imports.

Asan decided to solve this issue by producing cement with our resources.

Let's establish Hyundai's first production

plant without the help of foreign capital or technology! “

The Danyang Cement Plant broke ground in 1963 and was completed in 1964, the following year. It was considered the "March 1st Movement of Hyundai Engineering & Construction" as it revitalized the domestic construction industry by producing cement.

Asan encouraging workers at the Hyundai Cement Plant, which revitalized the domestic construction industry by producing cement.

Construction of the Pattani-Narathiwat

Highway in Thailand

In September 1965, Asan embarked on constructing the Pattani-Narathiwat Highway in Thailand, marking the first overseas construction venture by a Korean firm. Building a highway with traditional equipment on unfamiliar terrain alongside foreign workers was a monumental adventure.

Yet, Asan completed the project, gaining confidence that spurred further international expansions.

Construction of the Gyeongbu Expressway

An expressway was urgently needed for logistics purposes.

Leveraging his experience of building an expressway in Thailand, Asan initiated the project. Working day and night, Asan even forgot about profits.

The Gyeongby Expressway was completed on June 27, 1970, with a world record of 290 days, the shortest time in global history to build a highway.

Asan at the Gyeongbu Expressway construction site, which was completed in the shortest time in the world history of highway construction. (1970)

The final sealing of the Seosan Reclamation project, a major project that even changed the map. (1984)

Seosan Reclamation Project

In reminiscence of his father's vision, Asan dreamed of vast farmlands like the ocean.

Let's reclaim the West Coast,

create new land, and produce food! “

This is how the Cheonsu Bay reclamation project began. Asan developed stone quarries, transported rocks, and filled the sea. Using oil tankers with the 'Chung Ju-yung method,' the final dam was completed, creating 140 million square meters of fertile farmland (1.3 times the size of Ulleungdo Island).

Construction of the Jubail Industrial Port in Saudi Arabia

The Jubail Industrial Port being the largest construction project in the 20th century, Asan accepted the challenge by the world that ridiculed Korea as an underdeveloped country with no technology and financial capital.

He vowed to cut the construction time by eight months.

Winning the contract over companies from developed countries,

Asan surprised the world with the highest level of construction results.

Moreover, thanks to the advance project payments, our country's foreign exchange situations were significantly improved.

At the construction site of the Jubail Industrial Port in Saudi Arabia. (1978)

“ With our nation’s fate on our shoulders,

failure is not an option. ”

Following the contract signing ceremony for the Jubail Industrial Port in Saudi Arabia in 1976

At the launch event for the Pony, Korea’s first original model car. Asan fulfilled his long-held dream of making cars with indomitable will. (1985)

Automobiles

In 1940, Asan opened the doors to his auto repair business, 'Ado Service.'

He managed to reduce a typical ten-day repair period to just three days, mastering the structure of automobiles through repeated disassembly and assembly.

His shop became so renowned that cars from all over Seoul crowded to his store. Although forced to close his business due to Japanese occupation, Chung never gave up on his dream of cars.

Automobiles can measure a nation's industrial technology

and can be considered a moving flag. “

Though he assembled cars with help from Ford, this was not enough for him.

I will make a car built entirely

with our capabilities! “

Asan succeeded. He exported Korean cars worldwide.

By 2007, Hyundai Motors grew into a company with four overseas manufacturing subsidiaries, surpassing an annual sales volume of 2.6 million units home and abroad. Hyundai Motors, created with Asan’s dreams and passion, continues to race across over 200 countries today.

Korea's First Domestically Produced Car, ‘Pony’

Asan stopped forming a joint venture with Ford and instead chose to manufacture a domestic car using our own technology.

He still needed a place to learn the technology. Asan chose Europe. He commissioned Italy’s finest designers for the design and signed a manufacturing technology contract for crucial parts with British experts. He learned and refined their techniques to make them our own.

In December 1975, the first domestic car was born.

The first domestic car, Pony, made with our own technology just three years after breaking away from Ford. (1975)

X Car Development Project

The global economy suffered heavily from the second oil shock in the early 1980s, and Hyundai Motors was no exception. Determined to break through the downturn, Asan launched the 'X Car Development Project.' He invested 400 billion won to develop a front-wheel-drive proprietary model to enter the U.S. market. He also learned necessary technologies from foreign firms and built factories.

Adapting meticulously to the stringent U.S. standards, Korea's first front-wheel drive was launched in 1985! Named 'Pony,' it gained significant popularity in the U.S. and Canada. Asan’s vision and decisiveness paved the way for Hyundai Motors' success today.

Development of the Alpha Engine

The engine is the heart of a car. Even through we made our own cars, the engines were still imported.

It's been twenty years since we have been making cars.

How much longer do we have to rely on foreign engines? ”

Determined to develop our own, in September 1983, Asan launched a 'New Engine Development Plan.' He established a central research institute, gathered local and international talents, and sent them abroad for technical training. Two years later, the 'Alpha Engine' prototype was completed, achieving technological independence for Korea's automotive industry.

Overseas Automobile Production Facilities

Hyundai’s popularity continued in the U.S. and Canada. However, developed nations imposed protectionist barriers, creating challenging conditions for foreign cars to enter their markets.

As exports became increasingly challenging, Asan made a decisive move. In 1989, he established a production plant in Bromont, Canada, which was a crucial step for Hyundai in becoming a global automotive company. Since then, Hyundai has established local subsidiaries and production bases worldwide, becoming an international auto manufacturer.

“ Carrying a photograph of a sandy beach with only pine trees standing along the shore,

I went around saying, 'I'll build ships here, anyone interested? ”

From an early anecdote of Hyundai Heavy Industries in 1971.

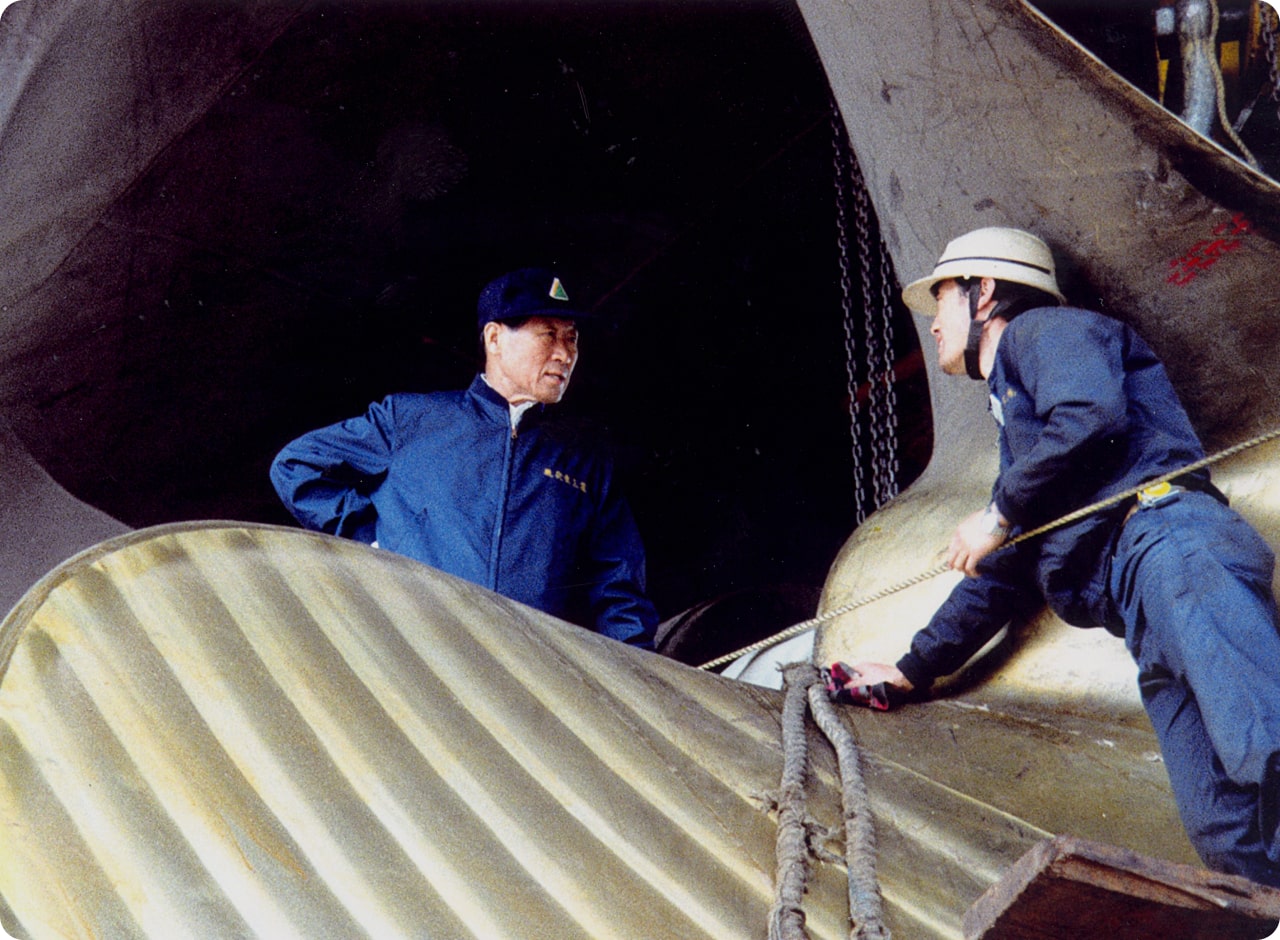

Asan encouraging workers at a shipbuilding screw deck as he greatly valued on-site management. (1983)

Heavy Industry

With the technology accumulated over the years,

it is time to build a shipyard! “

Despite the daunting costs and technological challenges, Asan faced another impossible challenge. Many mocked Korea when they heard it was going to build a shipyard. However, challenges are merely a stepping stone for leaps forward. To secure construction funds, Asan traveled globally, negotiating with investment firms, banks, and ship buyers. His plans were initially overlooked by others, but Asan was confident in his mission.

Eventually, he secured orders for two ships and secured loans. In just 2 years and 3 months, he not only built a world-class shipyard but also effortlessly constructed two 260,000-ton supertankers, astounding the world.

Today, HD Hyundai manufactures high-value ships with advanced technology, such as FPSOs (Floating Production Storage and Offloading units) and LNG (Liquefied Natural Gas) carriers. It is leading the world in shipbuilding, producing two large vessels per week. Fifteen out of every hundred ships navigating the world are built by HD Hyundai.

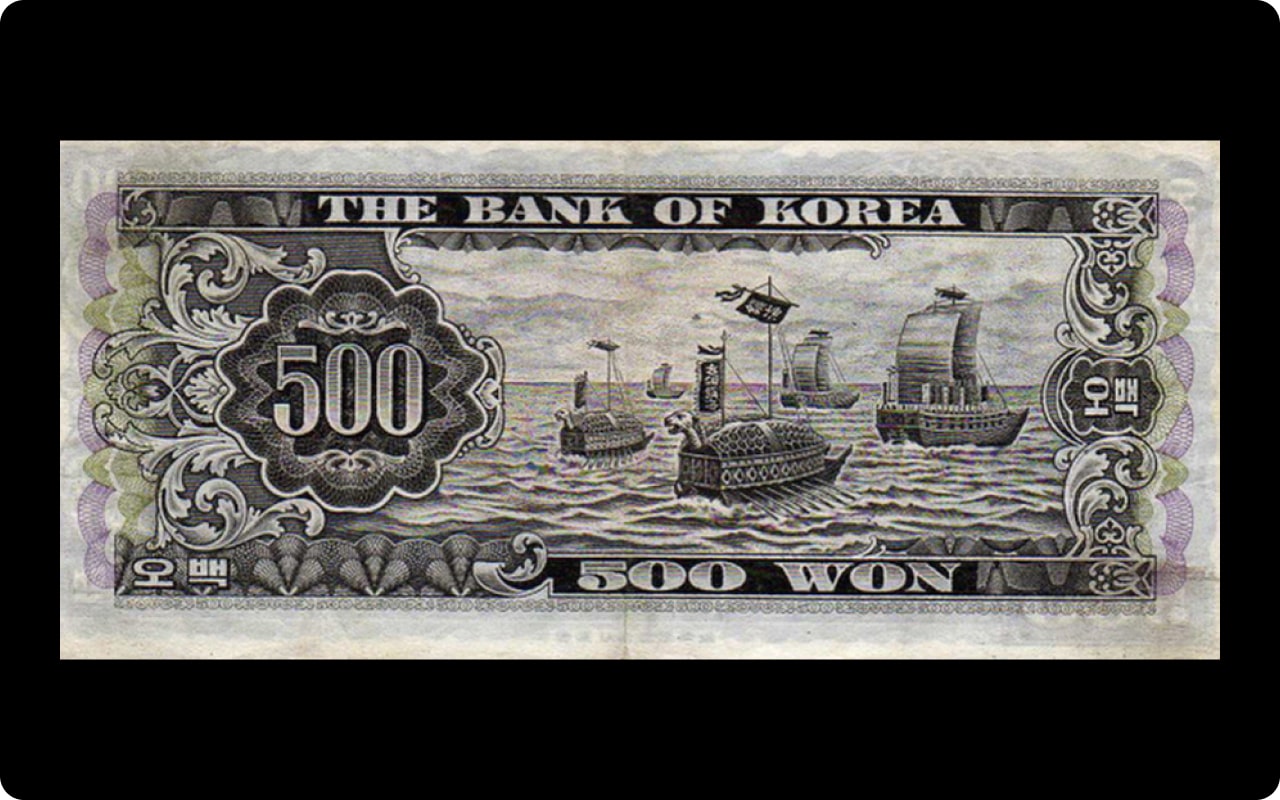

The 500 Won Banknote and Chairman Longbottom

No one believed a shipyard could be built. Securing foreign capital for funding was imperative. The skepticism about Korea's capabilities arose in a meeting with Charles Longbottom, the chairman of the investment firm "A&P Appledore," Asan pulled out a 500-won banknote printed with a turtle ship.

Our turtle ships precede British shipbuilding history by three hundred years.

Our potential has not rusted ”

Impressed by Asan's boldness, Chairman Longbottom opened his heart and decided to became a sponsor.

''Business Plans are my Expertise'

Persuading the Barclays Bank in the UK was the next step. When Barclays Bank asked about Asan's expertise, he answered;

Have you seen my business plan?

That business plan is my expertise. ”

Asan's belief that anything is achievable with full conviction moved Barclays Bank. The next hurdle was gaining approval from the British Export Credits Guarantee Department (ECGD). Asan went out to sell ships as the ECGD requested him to secure ship orders. A picture of a barren beach was all he had. Moved by Asan's determination, Greek shipping giant Livanos stepped forward. Finally, Asan was able to secure orders for two 260,000-ton oil tanker. It was his first major contract.

World Leading Shipyard

On March 23, 1972, the groundbreaking ceremony for Hyundai-Ulsan Shipyard (now Hyundai Heavy Industries) was held. The relentless construction work continued day and night and Asan envisioned a massive shipyard while watching the construction site. He often slept with his shoes on and ran into rainwater puddles to wake up and wash his face to start the day.

June 28, 1974. Two years and three months after the groundbreaking, amidst cheers and excitement, a massive block of iron sliced through the waves with vigor. The sweat and determination of Asan and over 17,000 men created the world's leading shipyard.

Asan encouraging employees at the Hyundai Heavy Industries inauguration ceremony (1973)

A panaromic view of HD Hyundai Heavy Industries. HD Hyundai Heavy Industries has become the cornerstone of the heavy industries sector, contributing to the industrial development of the country.